3220 Raymond Courier Automated High Capacity Tow Tractor

-

Flexibility

-

Scalable Solution

-

Fast Payback

By redeploying personnel to optimize productivity, Raymond Courier Trucks offer an industry-leading ROI under 24 months.*Fast Payback -

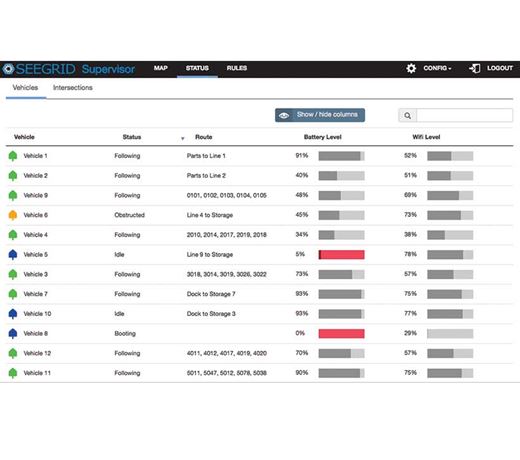

Fleet Management Application

The web-based Supervisor software monitors, controls and provides real-time vehicle data.Fleet Management Application -

Quick Commissioning Time

3220 Raymond Courier Automated High Capacity Tow Tractor Details

For indoor applications that need high performance towing capability, this Raymond Courier Automated Tow Tractor excels at automating repetitive, labor intensive and time consuming hauls that require heavy duty payload towing performance on flat ground or ramps.

- Battery: 24 volts

- Capacity: 15,000 lbs.

- Max Ramp Incline: 11% at 7,500 lbs.

*Actual savings and payback time for your specific location and application may vary. Reference our Raymond Courier Automated Guided Vehicles Brochure for sample application data.

Raymond 3220 Courier Automated Stacker - Product Information

Integrated Technology Options Increase Efficiency

-

Courier Automatic Charging System

24/7 Automated Solution For Greater Labor Efficiency With the Raymond Courier™ Automatic Charging operators no longer have to spend valuable time managing battery charging and maintenance for the Raymond Courier Automated Guided Vehicle – and can focus on more value-added tasks. -

Calculate Your Cost Savings by Switching to Lithium-Ion

Our line of lithium-ion batteries, compatible with our family of forklifts, showcases our dedication to advancement. These batteries are designed to seamlessly integrate into your lift trucks providing advanced data insights and wireless communication for remote diagnostics and upgrades. Use our Lithium-ion ROI calculator to calculate the cost savings you could be receiving by switching to Lithium-ion batteries within your current fleet.

Scalability

-

Scalable Fleet

With ease of implementation and operational Day 1, Raymond Courier Trucks work in tandem with your existing fleet and can expand fleet capacity for operational expansion. -

Multiplied Resources

One operator can manage multiple trucks at one time, while working on other value added tasks. -

Route Transfers and Flexibility

Routes can be easily transferred between Raymond Courier Trucks via USB to different facilities, locations, shifts or applications.

Flexibility

-

Redeployable Fleet

Operators can change routes in-house and through ease of programming and reprogramming.

-

Hybrid Versatility

Raymond Courier trucks can be used in manual mode as business demands fluctuate for operational flexibility.

A Range of Applications

From inbound to outbound and simple cross-docking to more involved workflows, Raymond Courier Trucks automate a variety of tasks in warehousing, distribution and manufacturing operations.

Reliability

-

Increased Productivity

Helping with labor fluctuations and shortages, the Raymond Courier Truck does what it is trained to do - on time, every time, any time. -

More Empowered & Productive Operators

By automating repetitive, low-value tasks, operators can be empowered by managing the equipment now performing the tasks they once did. -

Automating Labor Challenges

Supervisor Software provides vehicle data through and web-enables computer or mobile device, keeping your AGVs performing as programmed.

Support

-

Automation Implementation Assistance

Experienced consulting services, application engineers and automation systems experts are available to help you optimize your warehouse for automation adoption. -

Real Time Monitoring & Status Updates

Operate efficiently, productively and autonomously; we teach your people how to program and reprogram trucks without the need of engineers, but provide ongoing service and support whenever needed. -

Optimized Fleet & Labor Productivity

Our comprehensive telematics platform, iWAREHOUSE, is a data-driven tool option that works with all the trucks in your facility - manual or automated - to gain valuable insights into labor and fleet efficiencies.

Productivity

Applications

-

Horizontal Transport

Raymond Courier automated lift trucks provide a flexible, cost-effective, automated solution for repeatable horizontal transport tasks. Specific guidelines for each model and capability can be obtained from your local Raymond Solutions and Support Center. The 3220 automated tow tractor is suited for distribution and manufacturing operations, including pulling carts or trailers with heavy loads on flat ground or ramps in batch picking, parts-to-line- and end-of-aisle (automated conveyor cart) applications; and can operate under low hanging structures.