Byrne Dairy Increases Productivity in Cold Storage Warehouse

From Farm to Table: Optimizing a Dairy Distribution Center

-

CHALLENGE: EFFICIENCY WITH GROWTH

To keep up with growth, Byrne Dairy looked for efficiencies at its central cold storage distribution center, Syracuse Cold Storage. This 100,000-square-foot facility boasted 9,000 pallet positions with 16 loading docks. The company wanted to learn more about equipment and operations that could improve material handling processes and material flow at the warehouse. Byrne Dairy turned to Pengate Handling Systems, Inc., an authorized Raymond Solutions and Support Center, to help evaluate its operations. -

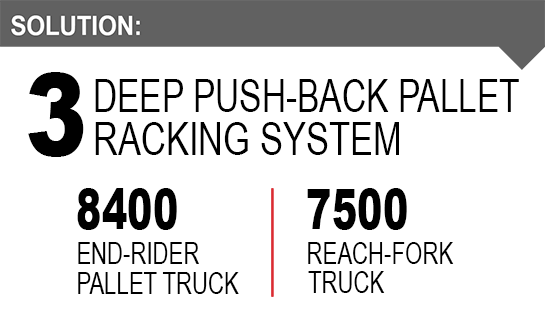

SOLUTION: ADVANCED SYSTEMS AND FLEET

In evaluating opportunities to improve efficiencies, the companies focused on the pallet racking systems and lift truck fleet at the cold storage facility, including product putaways and orderpicking, among other areas. Ultimately, the facility layout was upgraded to include a new, three-deep push-back pallet racking system to maximize use of space. Along with these updates, the company introduced a cold storage-equipped lift truck fleet for efficiency, including Raymond 8400 pallet jacks and 7500 reach trucks. -

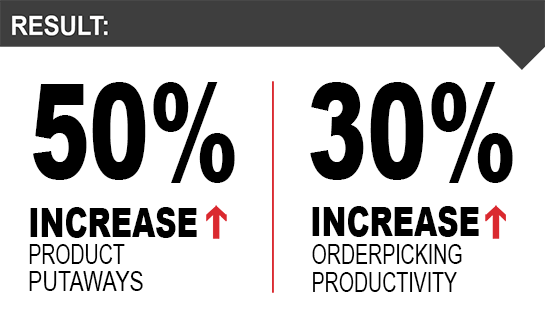

RESULTS: EFFICIENCY AND PRODUCTIVITY

Increased uptime — the upgraded lift truck fleet made an immediate impact with a laser-guidance system, which eliminates downtime for operators, and Raymond’s exclusive ACR System™, which requires fewer battery charges. It allows operators to move more pallets per charge, which helped move Byrne Dairy's Syracuse Cold Storage facility one step closer to meeting its goal of increased uptime and improved productivity.

FIND YOUR NEAREST SOLUTIONS AND SUPPORT CENTER

Related Products and Solutions

-

Reach-Fork Trucks

Raymond Reach-Fork trucks offer superior operator comfort, industry-leading performance, less maintenance and lower energy costs. -

Cold Storage Solutions

Our forklifts are engineered for high performance in all conditions, with cold storage conditioning packages that enhance performance and operator comfort. -

Consulting Services

Our Sales and Service Centers can provide you with customized solutions to maximize the efficiency of your warehouse facilities.