-

Create An Intelligent, Automated Warehouse

While automating your current operation may be intimidating, Raymond can simplify your adoption and implementation with an array of professional teams and tailored technologies.

Experienced consulting services, application engineers, and automation systems experts deliver integrated system solutions that include automated guided vehicles, storage and retrieval systems, and semi-automated operator navigation systems. All backed by the industry's most comprehensive telematics that offers data and insights to measure warehouse efficiency.

Our Automated Material Handling Solutions

-

Automated Storage & Retrieval Systems

AS/RS offer high-density storage capacity in a compact footprint, and can be tailored to your warehouse and distribution center needs. Designed as the center of an integrated material handling systems, AS/RS deliver the speed and efficiency required to be competitive in today’s supply chain and distribution center environments.

Learn More -

Conveyors & Carousels

The right conveyor system can speed order fulfillment, provide better inventory management and help accomplish lean goals for just-in-time and process controls. Whether you are moving individual products, full cases, or pallets, our engineering experts can recommend the appropriate conveyor equipment, technology, and material flow layout.

Learn More -

Industrial Robotics

Industrial robots can be designed and programmed to facilitate picking, packing and palletizing in your warehouse. Your local Raymond authorized Solutions and Support Center can recommend industrial robots with software, controls and vision systems to support a broad range of applications.

Learn More -

Consulting Services

From initial consultation to custom-designed solutions to long-term product and operational support, we offer an unmatched depth of warehouse solutions and material handling equipment to meet your specific facility, application and industry requirements.

Learn More -

Engineering Services

Our comprehensive engineering services ensure accurate design, installation and planning of your project — and accommodate any changes or alterations along the way. Combined with our systems integration and project management experience, you can count on achieving efficiencies and cost savings throughout the course of your project

Learn More

-

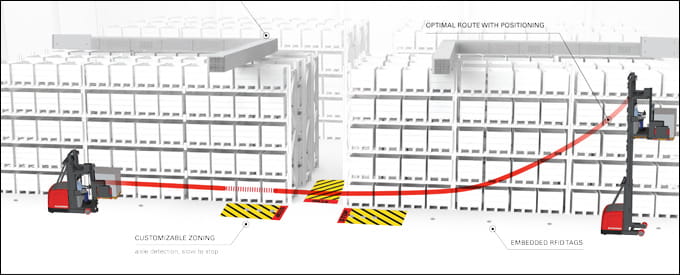

Zoning

and PositioningZoning and Positioning (ZaP) options ensure more reliable, repeatable truck operation by automatically controlling truck functions, allowing operators to focus on their surroundings and the task at hand.

Learn More -

In-Aisle Detection System

The In-Aisle Detection System is an application specific feature that automatically displays ‘sensor stop’ on the truck display, sounds an audible alarm, and decelerates a truck to a complete stop whenever it detects certain objects in its path (tractor first) and when locked on a wire in very narrow wire guided aisles.

Learn More -

Pick2Pallet LED Light System

The Pick2Pallet LED Light System is a pick to light system designed to help reduce picking errors by using LED technology to visually reinforce product placement for order fulfillment in batch picking applications.

Learn More

-

Optimization Before Automation

Before introducing automation into your business, your warehouse and processes should first be analyzed and optimized. Raymond Solutions & Support Centers can help lay the groundwork for a successful implementation by introducing our unique Lean Management System and by assessing everything from your facility layout to racking systems and forklift integration.

Advanced computer technologies are used to consider structural specifications, expected routes, material touchpoints, and more to create a warehouse that optimizes every interaction between associates, automated systems, and lift trucks.

Talk to us to see if, when, how, and where automation would make the most sense—and have the biggest impact—in your operation.

We provide world-class support tailored to meet your needs for maintenance and service – backed by response-time guarantees.

Our integrated network of more than 100 Solutions and Support Centers ensures consistency of service and allows our professionals and technicians to mobilize quickly to recommend and implement the best solutions for your business challenges.